Western Carolina University (21)

View all

- Canton Champion Fibre Company (2308)

- Cherokee Traditions (291)

- Civil War in Southern Appalachia (165)

- Craft Revival (1942)

- George Masa Collection (137)

- Great Smoky Mountains - A Park for America (2900)

- Highlights from Western Carolina University (422)

- Horace Kephart (941)

- Journeys Through Jackson (159)

- LGBTQIA+ Archive of Jackson County (85)

- Oral Histories of Western North Carolina (314)

- Picturing Appalachia (6797)

- Stories of Mountain Folk (413)

- Travel Western North Carolina (153)

- Western Carolina University Fine Art Museum Vitreograph Collection (129)

- Western Carolina University Herbarium (92)

- Western Carolina University: Making Memories (738)

- Western Carolina University Publications (2491)

- Western Carolina University Restricted Electronic Theses and Dissertations (146)

- Western North Carolina Regional Maps (71)

- World War II in Southern Appalachia (131)

University of North Carolina Asheville (6)

View all

- Allanstand Cottage Industries (62)

- Appalachian National Park Association (53)

- Bennett, Kelly, 1890-1974 (1463)

- Berry, Walter (76)

- Brasstown Carvers (40)

- Carver, George Washington, 1864?-1943 (26)

- Cathey, Joseph, 1803-1874 (1)

- Champion Fibre Company (233)

- Champion Paper and Fibre Company (297)

- Cherokee Indian Fair Association (16)

- Cherokee Language Program (22)

- Crowe, Amanda (40)

- Edmonston, Thomas Benton, 1842-1907 (7)

- Ensley, A. L. (Abraham Lincoln), 1865-1948 (275)

- Fromer, Irving Rhodes, 1913-1994 (70)

- George Butz (BFS 1907) (46)

- Goodrich, Frances Louisa (120)

- Grant, George Alexander, 1891-1964 (96)

- Heard, Marian Gladys (60)

- Kephart, Calvin, 1883-1969 (15)

- Kephart, Horace, 1862-1931 (313)

- Kephart, Laura, 1862-1954 (39)

- Laney, Gideon Thomas, 1889-1976 (439)

- Masa, George, 1881-1933 (61)

- McElhinney, William Julian, 1896-1953 (44)

- Niggli, Josephina, 1910-1983 (10)

- North Carolina Park Commission (105)

- Osborne, Kezia Stradley (9)

- Owens, Samuel Robert, 1918-1995 (11)

- Penland Weavers and Potters (36)

- Roberts, Vivienne (15)

- Roth, Albert, 1890-1974 (142)

- Schenck, Carl Alwin, 1868-1955 (1)

- Sherrill's Photography Studio (2565)

- Southern Highland Handicraft Guild (127)

- Southern Highlanders, Inc. (71)

- Stalcup, Jesse Bryson (46)

- Stearns, I. K. (213)

- Thompson, James Edward, 1880-1976 (226)

- United States. Indian Arts and Crafts Board (130)

- USFS (683)

- Vance, Zebulon Baird, 1830-1894 (1)

- Weaver, Zebulon, 1872-1948 (58)

- Western Carolina College (230)

- Western Carolina Teachers College (282)

- Western Carolina University (2008)

- Western Carolina University. Mountain Heritage Center (18)

- Whitman, Walt, 1819-1892 (10)

- Wilburn, Hiram Coleman, 1880-1967 (73)

- Williams, Isadora (3)

- Cain, Doreyl Ammons (0)

- Crittenden, Lorraine (0)

- Rhodes, Judy (0)

- Smith, Edward Clark (0)

- Appalachian Region, Southern (2940)

- Asheville (N.C.) (1944)

- Avery County (N.C.) (26)

- Blount County (Tenn.) (195)

- Buncombe County (N.C.) (1680)

- Cherokee County (N.C.) (283)

- Clay County (N.C.) (556)

- Graham County (N.C.) (238)

- Great Smoky Mountains National Park (N.C. and Tenn.) (525)

- Haywood County (N.C.) (3571)

- Henderson County (N.C.) (70)

- Jackson County (N.C.) (4919)

- Knox County (Tenn.) (35)

- Knoxville (Tenn.) (13)

- Lake Santeetlah (N.C.) (10)

- Macon County (N.C.) (421)

- Madison County (N.C.) (216)

- McDowell County (N.C.) (39)

- Mitchell County (N.C.) (135)

- Polk County (N.C.) (35)

- Qualla Boundary (982)

- Rutherford County (N.C.) (78)

- Swain County (N.C.) (2185)

- Transylvania County (N.C.) (270)

- Watauga County (N.C.) (12)

- Waynesville (N.C.) (86)

- Yancey County (N.C.) (72)

- Aerial Photographs (3)

- Aerial Views (60)

- Albums (books) (4)

- Articles (1)

- Artifacts (object Genre) (228)

- Bibliographies (1)

- Biography (general Genre) (2)

- Cards (information Artifacts) (38)

- Clippings (information Artifacts) (191)

- Copybooks (instructional Materials) (3)

- Crafts (art Genres) (622)

- Depictions (visual Works) (21)

- Design Drawings (1)

- Drawings (visual Works) (185)

- Envelopes (73)

- Exhibitions (events) (1)

- Facsimiles (reproductions) (1)

- Fiction (general Genre) (4)

- Financial Records (12)

- Fliers (printed Matter) (67)

- Glass Plate Negatives (381)

- Guidebooks (2)

- Internegatives (10)

- Interviews (815)

- Land Surveys (102)

- Letters (correspondence) (1013)

- Manuscripts (documents) (618)

- Maps (documents) (177)

- Memorandums (25)

- Minutes (administrative Records) (59)

- Negatives (photographs) (6090)

- Newsletters (1290)

- Newspapers (2)

- Notebooks (8)

- Occupation Currency (1)

- Paintings (visual Works) (1)

- Pen And Ink Drawings (1)

- Periodicals (193)

- Personal Narratives (10)

- Photographs (12976)

- Plans (maps) (1)

- Poetry (5)

- Portraits (4568)

- Postcards (329)

- Programs (documents) (181)

- Publications (documents) (2443)

- Questionnaires (65)

- Relief Prints (26)

- Sayings (literary Genre) (1)

- Scrapbooks (282)

- Sheet Music (2)

- Slides (photographs) (402)

- Songs (musical Compositions) (2)

- Sound Recordings (796)

- Specimens (92)

- Speeches (documents) (18)

- Tintypes (photographs) (8)

- Transcripts (322)

- Video Recordings (physical Artifacts) (23)

- Text Messages (0)

- A.L. Ensley Collection (275)

- Appalachian Industrial School Records (7)

- Appalachian National Park Association Records (336)

- Axley-Meroney Collection (2)

- Bayard Wootten Photograph Collection (20)

- Bethel Rural Community Organization Collection (7)

- Blumer Collection (5)

- C.W. Slagle Collection (20)

- Canton Area Historical Museum (2110)

- Carlos C. Campbell Collection (462)

- Cataloochee History Project (64)

- Cherokee Studies Collection (4)

- Daisy Dame Photograph Album (5)

- Daniel Boone VI Collection (1)

- Doris Ulmann Photograph Collection (112)

- Elizabeth H. Lasley Collection (1)

- Elizabeth Woolworth Szold Fleharty Collection (4)

- Frank Fry Collection (95)

- George Masa Collection (173)

- Gideon Laney Collection (452)

- Hazel Scarborough Collection (2)

- Hiram C. Wilburn Papers (28)

- Historic Photographs Collection (236)

- Horace Kephart Collection (861)

- Humbard Collection (33)

- Hunter and Weaver Families Collection (1)

- I. D. Blumenthal Collection (4)

- Isadora Williams Collection (4)

- Jesse Bryson Stalcup Collection (47)

- Jim Thompson Collection (224)

- John B. Battle Collection (7)

- John C. Campbell Folk School Records (80)

- John Parris Collection (6)

- Judaculla Rock project (2)

- Kelly Bennett Collection (1482)

- Love Family Papers (11)

- Major Wiley Parris Civil War Letters (3)

- Map Collection (12)

- McFee-Misemer Civil War Letters (34)

- Mountain Heritage Center Collection (4)

- Norburn - Robertson - Thomson Families Collection (44)

- Pauline Hood Collection (7)

- Pre-Guild Collection (2)

- Qualla Arts and Crafts Mutual Collection (12)

- R.A. Romanes Collection (681)

- Rosser H. Taylor Collection (1)

- Samuel Robert Owens Collection (94)

- Sara Madison Collection (144)

- Sherrill Studio Photo Collection (2558)

- Smoky Mountains Hiking Club Collection (616)

- Stories of Mountain Folk - Radio Programs (374)

- The Reporter, Western Carolina University (510)

- Venoy and Elizabeth Reed Collection (16)

- WCU Gender and Sexuality Oral History Project (32)

- WCU Mountain Heritage Center Oral Histories (25)

- WCU Oral History Collection - Mountain People, Mountain Lives (71)

- WCU Students Newspapers Collection (1923)

- Western North Carolina Tomorrow Black Oral History Project (69)

- William Williams Stringfield Collection (2)

- Zebulon Weaver Collection (109)

- African Americans (390)

- Appalachian Trail (35)

- Artisans (521)

- Cherokee art (84)

- Cherokee artists -- North Carolina (10)

- Cherokee language (21)

- Cherokee pottery (101)

- Cherokee women (208)

- Church buildings (190)

- Civilian Conservation Corps (U.S.) (111)

- College student newspapers and periodicals (2012)

- Dams (108)

- Dance (1023)

- Education (222)

- Floods (61)

- Folk music (1015)

- Forced removal, 1813-1903 (2)

- Forest conservation (220)

- Forests and forestry (1197)

- Gender nonconformity (4)

- Great Smoky Mountains National Park (N.C. and Tenn.) (181)

- Hunting (46)

- Landscape photography (25)

- Logging (119)

- Maps (83)

- Mines and mineral resources (9)

- North Carolina -- Maps (18)

- Paper industry (38)

- Postcards (255)

- Pottery (135)

- Railroad trains (72)

- Rural electrification -- North Carolina, Western (3)

- School integration -- Southern States (2)

- Segregation -- North Carolina, Western (5)

- Slavery (5)

- Sports (452)

- Storytelling (243)

- Waterfalls -- Great Smoky Mountains (N.C. and Tenn.) (66)

- Weaving -- Appalachian Region, Southern (280)

- Wood-carving -- Appalachian Region, Southern (328)

- World War, 1939-1945 (173)

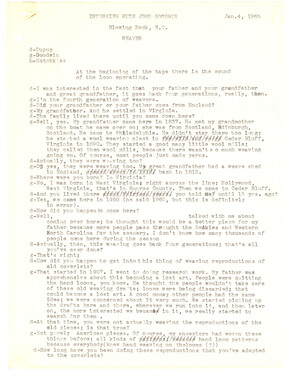

Interview with Wayne Carson

Item

Item’s are ‘child’ level descriptions to ‘parent’ objects, (e.g. one page of a whole book).

-

-

1 Wayne Carson Name of interviewer: Jeff Seymour Name of interviewee: Wayne Carson Date of interview: November 21, 2002 Length of interview: 1:01:01 Location of interview: Buncombe County, NC START OF INTERVIEW Jeff Seymour: Seymore interviewing Wayne Carson JS: I guess Well start at the beginning. So, where you born? Wayne Carson: Canton North Carolina May the 9th 1939, a long time ago. [Laughter] JS: How long did you live in Canton? WC: Until 1961, here I am about 10 miles away in Buncombe county of course Canton being in Haywood. But me and my wife were young and found this little old farm when we were young and was able to buy it. So, I raised my family here and of course Canton and Haywood is kind of always home I’ve worked there about 36 years at this paper mill we’re going to be talking about JS: So, when did you start working at the paper mill? WC: 1959 I would have been let me think a few months of being 20 so I was 19 in 1959. Like I said, let me go back just a little bit. well we lived there in the city limits not downtown but over on the hill looking at the plant all these years growing up not realizing that, well at least I never did plan on working there but like you’ve probably talked about or it might be on your study. A mill town a lot of families built around the fact of the paper mill and the industry. So here I am looking at it from a very small boy up through my youth and you know I did go out and look out the window but I generally went out in the yard and you hear it even if you’re there even within a few miles there’s a real rumble. There’s something always happening at the plant but if there was a shut down or something it was unusual how quiet it was. It wasn’t that great of a noise but it’s still a noise. WC: I went to public schools there, grammar school and high school and in my early years I walked to school and I walked by the plant going to high school especially and I still not realizing that one of these days I would be working there. So, in about 57 or 58 they started hiring, well here I am young man I was working in the store business, a grocery store. That was my I guess you might say a trade. But they were hiring young, well I guess they would hire anybody but basically younger. They were having a lot of old people retiring and then they was putting in a new paper machine and they wanted about 500 more people by the time this got in and installed and so on to add more production and more workers in the plant. So, I was encouraged by an older family and other friends to go down there and put in an application and I drug around for months. [Laughter] I didn’t have that real desire I mean there wasn’t nothing wrong with it but. And finally I did and in a few weeks they called me and we went through the 2 Wayne Carson process of an interview and going to the doctor and the hospital you know they wanted you to be in good shape so I passed all through the process and was able to go to work. It was February 1st, 1959. JS: What did you do once you got to work? WC: Well you go in on 3 months’ probation and this might be relevant or not to your study, but I was hired about a 1.69 an hour for 3 months. And that doesn’t sound like very much, but you got to think about in the later 50s gasoline was like looking back and around 28 cents a gallon. Let’s see kerosene would have been less that .20 and a loaf of bread about .20. But then again money was money. Fair good jobs would make 30, 35, 40 thousand and everything else is higher. And back in the later 50’s a good ford or Chevrolet a new one would have been about anywhere from around 2,800 or 3,500. You see the 1.69 now in 2002 don’t sound like very much but I was surprised to get the job and for 3 months you was in a probation period to see how you done and after 3 months you was, I don’t know of anyone over the years that couldn’t make it 3 months and behave. [Laughter] But then you went to, you got a raise, lets see a dollar eighty-nine and then you started working up through the system to generally you was vacationary placement and whatever the department they put you in. They have what you call a transfer pool. A boss or a supervisor over that where the new employees was assigned generally per week and when you would, and everybody punched a clock they give you a number and you kept that number all your time and I still remembered mine and I’ve been gone about 9 years. [Laughter] When you punched in they wanted you to go to a different place that day they had a paper punch card to tell you to go here and go there so generally they tried to schedule you by the week an you would go to that department you would just be the vacationary pass? Not necessarily someone on vacation but the lower younger employees done the bottom jobs like cleaning up, moving something you know? JS: A little more manual labor jobs WC: and then being like the operator or [inaudible] driver or something or other. JS: So, after you were there for 3 months you kind of got a more permanent position? What did you do in the mill? WC: The next thing was to, as you become a young employee you wanted to get into a department do you could be stationary and not shift around. So as openings come, I started working what you call roll storage which had to do with after the paper came off the machines and them rolls we stored it they had orders on the rows and they threw this storage department, so it went from storage to the shipping or they had what we called the finish room that took the rolls of paper and cut it into sheets and all smaller sizes for customers and then it wasn’t all supply cores for the paper machines. Certain sized rolls of paper was rolled in cores. And they cut the cores and then on the excess paper was called broke. That meant discarded or unusable to the customer. So that they would run that bac through the system in the beaters. It 3 Wayne Carson was more than just saying were in a big warehouse and were breaking the paper. It’s a bigger process than it sounds. So, I worked in there, and later got a transfer and then started in at the bottom and that particular department as a vacationary placement. I worked in that department for about 3 years and I transferred to the lower end of what they call in the mill, the chemical area. All of this was before we ever had a union. ?? JS: So, when you started working with the chemicals what was it like? WC: Well they especially in years past they may have bought their own chemicals in order to, for the pulp process. Well actually in the chips they used to chip their own wood and today in 2002 you see chip cars coming in JS: Yeah you see the 18 wheelers on the highway WC: So they’re chipped at a sawmill or they do have chippers in the woods like in SC, NC or GA and they take the wood cutters takes their wood by truck to the chipper and they chip it down there load it in the big rail cars that you see coming into Canton and those that aren’t too far off especially the saw mills they used to have a lot of slabs to square up the logs and that was just used to burn or other purposes but now they don’t waste anything. But now they take the slabs off the saw mill and chip it up and bring it over there and it makes chips. No longer, well when I went to work, we did all the chipping at the plant in big chippers. And round wood, like wood cutters would bring in all sticks and wood certain lengths and so on. But in this chemical process we made caustic soda, which is used in other things. Bleach and the mixture of these chemicals had to do with cooking the chips. What we called at the paper mill was the digester, but I imagine if you’re gonna can beans on a cook stove is the pressure pot. You fill it up with chips in these pressure pots, they was like 3 or 4 stories high. These pressure pots were about 18 to 20 cords of chips would fill them up with chips and then run these combinations of chemicals in it. One was called white liquor, not having anything to do with liquor but it was made with lime, caustic and other chemicals in the liquid form they would run that in the digesters to process it through the technology over the years to narrow it down and test how much this particular chemical to run in the digester in order to cook these chips. They would circulate, put those chips on steam pressure and they would circulate this chemical through it while it was cooking about 2 hours’ time. And that would literally break down the wood chip and to break down I think they called it [inaudible] That’s what holds it together JS: You’re extracting the fiber from the wood? WC: And that would break that down all they had to do to pull it out was to open a valve on the digester and the pressure in that pot would blow it into another pit. And on top it would have a steam release this huge vat and after that they would wash and pump it then out of that vat and put into a what we call washers. Out of one huge storage vat it would be pumped in another and it would go over into a drum which had a vacuum on it. It would suck and catch this cooked wood and that would be like a black or real dark brown cause its not bleached or 4 Wayne Carson anything they’re spraying fresh water that goes across that drum from that vat into about 4 or 5 6 vats to down at the end this its as plane as could be it wasn’t near as dark looking cause they’ve washed it. Then it was pumped into more storage tanks and then it went through the same process with bleach and today they don’t use the chlorine blech they use oxygen process because they found a better way. With chlorine there was dioxide. Which the bleach got into the river over the years and they’ve learned over the process of doing that. Bleach is an oxidation process which is somewhat bleach and other products that are used in a different way than its used today. And it comes out white I mean white as snow. I could bleach and therefore its ready to go to the paper machines and then at the paper machines one machine will have color papers with order for red, blue, green they had the dye in the process. Cause the machine the others might be various shades of white really. JS: Like off white, beige stuff like that? WC: they have their company name on all these grays. And then they always made heavier boards out of this for stock or food carton stock. And they have one huge machine there now um 19 machine that processes and theirs is a whole lot thicker and they make it there ship it to Waynesville plant and coat it with polyurethane and then cut it into different sizes and of course used to be champion papers now the employees was able to buy it out along with investors and named it blue ridge paper products. By the way one of the companies was always a side track of champion or another like general motors would be the main one, but they have Buick Chevy and others. [Champion had this side pact. So blue ridge was able to buy a pact Process that makes the car and does a lot of research are all part of the company.] JS: That’s in Waynesville? WC: No, it’s out the basic plants of blue ridge paper is canton and Waynesville, but they have 5 or 6 other packaging plants that finishing plants besides just the board side. Here at champion anymore, Blueridge anymore they don’t cut so much sheets of paper, and send the roles and let them do it and they and lets say what would you call it downsized enough so they just want to let some body else do the other process. JS: Right, so in my studies I found that champion paper mill big contribution is that they got the chips there, thy cut it down and they made the paper and they had the finished product and they shipped it out and that’s one of the reasons they were so successful in the early 1900’s when they first started it was a paper mill that was their thing that they did it all. WC: Now let me go back just, over the years they still got some byproducts that through these chemicals and always saving of any in other words, everything is not just dumped into the river or waste treatments after the cooking process they save and are able to salve turpentine from the pinewood. They get turpentine steel, and this still works like an alcohol still, a liquor still and its huge. It would be like a still at Budweiser beer. But it well what it does is purify the turpentine and there’s water and they take the water impurities out and then sell it. There’s 5 Wayne Carson another product after cooking the chips that’s called Prostaller it is used in cosmetics, soap and all kinds of lady’s stuff. It’s a dark sticky and it’s not black it’s a brown and its used in some foods you would be surprised. That’s 2 products I know they still use. But back over the years when they was in bleaching, they had a product called SoHI, which is like the same thing as Clorox and that that was their brand name. they sold Sohi and marketed it but over the years like lots of other industries they wanted to get down to just paper, not so much. But like I say anything that they can salvage they can still have some byproducts that they can use to make money but back over the years they also sold the caustic, they used caustic in in what do you call, textiles. Places like American ink they used non caustic or in Princeton print works they used caustic. Caustic was used in several areas of other manufactures, they made it and for the process and used the chemical and they had some leftover so over the years they had a lot of different side jobs but today its basically just paper and board and milk cartons. JS: So, you said you didn’t initially growing up looking at the paper mill that you didn’t wanna, well you didn’t think that you would grow up and work there your whole life. WC: I didn’t want to that wasn’t my goal. Although my daddy he was it was good that he was still working there when I went to work as a 19-year-old. and he was there, let’s see he retired in 1970 so I was there about 21 years before he retired. And going way back in history to champion which their first production they started building the plant 1905/6 and I think the day was in 1908 when the first production was started and a lot of people around in those early days, it wasn’t unusual for somebody to go down there and work a month or 2 or 6 and then quit. Now days you got a good job generally you don’t quit you hang on. But over the years it got to be a better place to work and then in the early years being here in these mountains the mountain people of course the other people came in from other places to work here but in general the biggest work force was the men they were from Buncombe and Jackson counties from the surrounding counties. A lot of these folks were fountain folks and farmers used to living on the land and they might work a year or two and not quit and they reckon they can make just about as good as mountain farming and 2 plant work is not for everybody. So, Mr. Reuben B I guess you studied some? JS: Yeah, I’ve studied some. WC: he initiated the probability of a bonus if you’ve been there 5 years and you’ve got 5 years loans for instance if you’re making a dollar an hour which would have been a whole lot back then. A lot of them worked for a dollar a day but their wages is as good as any other plant always has been. But me and you may be working side by side but if you had your 5 years you would be making 5% and that stretched up to 25% even in my lifetime I was work side by side making 25% a quarter on the dollar more than I was doing the same job. JS: Well I mean you got to take care of your employees though. 6 Wayne Carson WC: Well that was an initiative to get the money and it worked over the years and then in the 60’s they we got into production bonuses and they combined that with the bonus and tacked it onto the base rate of the whole mill and it phased out eventually. And with especially the younger employees over the years have always griped “you’re making more money” doing the same job. It what didn’t become a big issue the company and the decision was to combine a bonus that production bonus with the wage bonus and give everyone a raise. Raise everybody’s wages and everyone would eventually be making the same after a few years you know. JS: Okay well you were saying that you didn’t wanna, or you didn’t think you were going to go work in the paper. But I’m sure it played a huge role in your life; I mean living that close to it and looking at it every day. You know the high school is right beside it, so did most people go to work for them? WC: Well a lot of people they have, and maybe trough the early years if your dad worked there or family you had a assured of a job that you could work there and so saying that my dad and even my family. For a fact I didn’t know, but over the years the employment process changed to used to you would go to the company and put in an applications and now you go to the employment security commission in canton and then and in the last few years they have to hire so many black and so many women and so many veterans and In the national government all those things are probably necessary now in years gone by in the early years it probably wasn’t and it wasn’t really discriminating against people, but we’ve always had for instance black people that worked there. But still the process s still a little bit different than here back in 63 and I look back and see things and its just the way it used to be. And I think the national country as a whole has had better days from what it used to be. So as looking back there my grand daddy worked there some he didn’t retire, and I had always hear that my granddaddy said he always use to take him his dinner when he was at the plant. And I know you’ve seen some of those old monthly champion logs. I found my granddaddy’s picture in there and I didn’t know it was there in 1922. And I don’t have it here with me there, but I have a copy of it. JS: Well that’s cool WC: yeah, it’s pretty cool. But he was one of those folks that he worked there more than one time and then he was my old time business man. In other words, he had a shoe shop and a cafe and in the early years in the 20s and 30s he had a pot factory and all those locks was done by hand and its not like it was today. And he was in the farm and he enjoyed doing something like that better than he did working the plant and he didn’t work there too many years, maybe 10 or 12 years. But my daddy did retire there, and I was fortunate enough to in 1995 they offered, they were cutting back on the workforce and I didn’t get fired nut they offered an initiative to the employees a retiring package. And I couldn’t afford it, but I liked to have had it. But I was able to take their package and retire at 55. JS: Oh that’s nice [laughter] 7 Wayne Carson WC: So, I haven’t looked back and I’m enjoying retirement and I’ve lived this long and gosh its been 8 years. And I have an everyday grind [laughter] not that I hate it I was there 36 years. JS: That’s a long time WC: and then a shift worker that its basically the mill workers accept maintenance in general they of course other jobs as they were a shift worker for about 25 years and then I went into maintenance Now when you’re a shift worker, days is the worst shift. JS: yeah? WC: yeah because it was more laid back on through the graveyard all of the big bosses, the day bosses is gone, and it don’t mean that you cut up and goof off. Its just different. [laughter] JS: oh yeah, if the boss man is right there its always a little different than if he’s not. WC: and then you got all the really big superintendents I don’t care who you are even if you’re 25 of 50 when the big superintendent is there it’s always a little bit different. Over the years no body put. [TAPE GOES SILENT 30:27-30:40] WC: Now going back to I guess; you’ve studied it Mr. Peter G Thompson the founder of champion paper come down here from Hamilton Ohio and of course you’ve read about him and I’m going over stuff you already know. But he had a boy in Asheville in private school a school for boys so the process in Hamilton the parent plant of champion was they didn’t cook wood, the bought pulp from other companies and in that area that cooked and processed the chips and the mill that’s there today is no longer champion paper. They still don’t and never cooked wood. He was interested, and he was in paper he would buy paper already made, rolls of paper and run it through his paper mill and make sheets and so on to sell to customers he was not completely satisfied with the paper and the pulp and he was paying a high price in order to get a greater return he was traveling in this area, by train to come to Asheville. He loved it here in these mountains spruce and of course chestnut and poplar and other hard woods. He got this idea and in this idea that set up a pulp mill here. So, our plant in canton was started as pulp making, not a paper mill. So he shopped around from Asheville to murphy looked at a lot of land and water and communities and over a period of time I would say maybe as much as a year with a friend that he met to negotiate with Smathers and he had advised him on the land and he was not only a layer in land of course and this being very sparkly populated the rail road had just gotten into WNC about 1892 when it got to canton with what they call from Asheville to murphy is what they call the murphy branch. All this opened this area and of course had a lot to do with him being able. So he chose the site and he found some land on the I guess you call it west fork of the pigeon river. ? which was the head waters of the on the west fork of the pigeon river some of the areas in there’s called right hand prong, left hand prong and middle prong which had been the main prong of the west fork but he purchased the land about 9,000 for 8 Wayne Carson 1200 acres for [inaudible] and purchasing land here in canton and negotiated with some town fathers where the plant is today and was able to start building the mill and the first days of the idea was to build a flume that’s where a big water would flow from sunburst about 12 miles or so down to canton and then flume to lumber and the wood one of these ? had a look at it and said that would be the way to go. But by the time he purchased the land for the plant and the timber area that he first purchased another engineer said well you have to have to get into the flume in sunburst it will have to be 150ft high to get the fall? And he figured that would be impossible so after already getting the right of way for the flume through all the country land owners, the farmers and so on had to go back and get another right of way for the rail road. [Laughter] and basically for the flume would be still it would be go through each induvial and each landowner. So one time the rail road running all the way from canton to the foot of the mountain and of course later on the trains had engines ??? and that got started in part of the lumber, most of the lumber I would say [inaudible] when he builded the plant the lumber came from that area. With a smaller saw mill and not a lot of equipment to be drug up ?? horses, mules and all of this and cross cut saws and land power. And of course saw mills pulled a steam engine and then within a few months and so on they was able to start getting shay engines, that’s a geared engine that went up as much as 12% of grade and the other engines about 4% ??? but a geared engine was a slow engine but all the wheels on it pulled on it for years we didn’t have the big side rod kind of like, more than a 4 wheel drive [laughter] all of that was that process and so building the mill and of course in the woods it wasn’t just cutting wood for the plant, that was a side the lumber business so everything wasn’t lumber saw material, after they got the plant build and all they needed was sold in the lumber market and of course they didn’t throw away all the scrap or some pieces was chipped and all of the lumbers was in the mountains. Wood part of it would go for the pulp and smaller stuff but any big timber actually made money by making it into lumber. So after a couple of years they got into a company in I believe either PA or NY is from Whitmire logging company was n the wood business and they kind of merged with them and they promised them MR. that they could supply the wood to the mill and keep it going and in the early years that was a big thing to have enough logs coming in to keep the mill going day in and day out. Especially winter time its worse and actually all of this was done by hand, no trucks and so on. And so that didn’t last too long and so they didn’t live up to their promise and champion, what’s that word? They took it back over. JS: Champion took over the timber industry? WC: from this Whitemire, in about 1912 champion wanted their own hands in the paper mill and in the woods. See sunburst had as many as 500 people working it was a small town in the woods in that sawmill in that process. They wanted more to make paper and, in the factory, so they merged with Pressmont Lumber company and they were doing some more lumbering for them and it maps [inaudible] NC and the lower end of pigeon river where today is where the Walters family is down there in TN. And so someday Pressmont and the Robinsons were caught, or they say they got to have it here in the mountains. The Robertson’s but everyone 9 Wayne Carson grew up saying Mr. Robinson [laughter] but they merged and called the lumber company then Suncrest. Took the sun from sunburst and crest from Crestmont and so this new company basically took over all champions work in sunburst area and I forget how many. So, over the years they would buy more parcels as a far as graveyard fields today to shining rock and all of those Pardee [inaudible] Big Sam all that thousands of acres, nettle prong, right hand prong, McClure creek now you talk about a big operation. So anyway, Suncrest brought heavier and bigger with the merger too they were just in the wood business. Moore got over head skidders. JS: What’s a skidder? WC: It’s a huge steam powered with a huge boon that they would take back into the mountains and put on a side track and tie the boon off with cables, stretch in and quarter cable steel as far as a mile over to anther mountain and now they had it so heavy they would take a mule of something to pull a small cable ½ steel cable over and chose a good stout tree and after the tree off with cables to where it wouldn’t break or move. Put a block in it and put a small cable through tree pull it back to the skidder and he could pull the inch and water cable over and tie it off over at the other end and then they would run a small trolley and they could pull wood over a ravine where they wouldn’t have to build a railroad, they called it an overhead skidder. It stayed stationary and it might set up if it was a great area some places in there I found that for instance, where one was set up not on top of Sam’s knob but in that area, sat there as much as 2 years in one place and skid all of the area. And what they would do is bring 3 to 4 logs and cut it a mile off and a man would signal and they would cable down, the smaller cable maybe a 3 quarter cable or an inch, down with the wood and grab 3 or 4 logs which was basically 40 foot long. And bring it over like I said as far as a mile away over, near the track where then the loader that loaded all the cars at the saw mill which may have been 15 miles back from [inaudible] but then they would wear this whole area out then they would move on down and around the mountain wherever and send the skitter out again. But the overhead skitter did a lot of damage because you could image as they brought it and say they would move the line and set it on one point over there and maybe 3 or 4 and move the other end. And so although he’s staying in one place, and before the time was over and dragging the timber, it looked like you’ve seen some old pictures, maybe more like and it looked like WWI in Europe where all the trees and all that’s what it looked like in the early days with the wood JS: And they just left it too WC: Yeah, they just left it all. And now I got side tracked. I may [Laughter} you may need another tape. JS: That’s okay I got another tape too WC: This doctor Sheek. George Vanderbilt did Biltmore forest, he brought into this country in 1892 something to be his forester. They was no professional foresters in the area. And he set up a forester school and I think if you visit there today there’s a lot of history there too. But as 10 Wayne Carson long as the early 1900’s Mr. Sheek would not only get his students class room instructions but then they would go out in the woods and it was a practical like for instance a particular week they might they would move all they would have and go over across the mountain to sunburst. And look at their wood operation and see forestry has not only to do with harvesting but replanting and replanting to protect them. Now Mr. Sheek was a German [inaudible] But he had not seen in America like it was in the old country where there were more particular and he over the years was heartbroken. Let’s see the sunburst operation [inaudible] His operation so therefore I was telling you about the old skills but over the years him and George Vanderbilt parted company and he went back to Germany and let me back up just a little bit. Him and George parted company because actually George Vanderbilt ran into hard times although he owned thousands of acres. Biltmore mansion and farms and everything else back in the early 1900’s he ran into financial trouble. He didn’t lose anything. JS: Right WC: he talked about of all his vast land ownings people working of course those he ran out of money so him and Dr. Sheek parted company and he kept his school going not connected with George Van and he would go to like Michigan and set up and they would study in that area for a few months, washing state and was able to then to take his class to sunburst and Mr. Rueben and study and watch the wood operation and hands on and be in the woods and see what is going on and he is training all the fellows with what to do and what not to do and his students would go on then, especially in the earlier times of 1900s and 1800’s and they would after graduating from his school would be able to go to some lumber company and be their forester. JS: Ah okay WC: So, they could tell these companies how to do it, what to do and what not to do. But to get to what I was going to say a minute ago, [Laughter] He went on back to Germany and might have visited over her a few times nut In 1952 he came back and visited Mr. Report B and this was after the sunburst operation and all the wood was all over and lake Logan was built and so on and later company headquarters and all of the facilities in lake Logan were able to renew all appliances and him and Mr. Reuben B went back into the woods and I read his biography an he was amazed that this spot was all torn down and was so steep and it would be so hard to literally plant trees without pots and it’s been reforested by ? and he was amazed how, let me use the word loosely nature, really gets down and the lord how he restores things and he was amazed at how hardly any sign was seen of the destruction of a few years ago. And as you’ve been in the woods and me too you hardly see that side. Now one of the biggest things which hey could not help was some of the history of that area is what stopped the sunburst logging operation is a fire started in 1925 in graveyard fields. JS: Okay, I was about to say yeah you go to graveyard fields and see some… 11 Wayne Carson WC: it burned an estimated 25 to 30 thousand acres up there now that’s where they were logging and they lost a lot of timber that they already had in the woods ready to be pulled out and then they just cook and it was said it was destroyed 25 or 30. And today even that would be about 70 something 80 something years fire would be 2 days before thanksgiving in 19225 and I think it was from there to right before thanksgiving in 1925 and today you go in that area, big Sam, black balsam, graveyard fields and on out towards shining rock and it burned all the way out there. And you think by about [inaudible] because the trees is still hardly from what I’ve read it literally cooked the ground and like where there was that area was full of spruce which is a pine and where they cut the stumpage once those stumpage in that rich pine it just kept burning in the ground that’s the reason why that area today, and its still a unique area its beautiful I could say if you’ve ever been out west you would think [inaudible] about western north Carolina and even today its reforesting itself. It wasn’t for the damage in that are was the fire. And two ways, three ways I never did now where the fire come from. 1925 was one of the driest years in WNC and they had smoke spark a fire? which is a big old bugle a big not straight stack and that was in a [inaudible] that had sparks that go out and stay in and burn itself. Something else I read through champion history, had a man where the train went with a man with it on the side of the woods might have sparked this particular year. So, the three ways I read, in that time a lot of people smoked either somebody was careless with a cigarette or a spark did come from one of the trains and the third way it didn’t have any somebody could have set a fire. The fire burned 2 to 3 weeks and burned itself out, rain eventually would come, and they had to go back in and build lots of trusses because over the ravines and creeks lots of trusses in the mountains in the woods to get their equipment. It would cease the sunburst wood operation now over the years it eventually went to the government and champion kept some of the land not bac in the high part and they were able to contract some of it out, small amounts no big operations. So Suncrest which had the big band mill being at the time down at where lake Logan is moved from there and set up a mill in Waynesville and this was 1926/27 in there. So, the town ceased to be, they didn’t burn in down or tear it down but the saw mill operation was dead. These articular towns was, had all the necessities of a town anywhere and what they called a commissary, now I call it a K-Mart is a company store which they had everything you needed a church a jail a school housing hotel many things they even had electric ice in that day to ? now. But somebody had a lightbulb in a living room and was able to back in the woods back at the logging camp they run a telephone line back to the woods so they had a telephone system of course it was sort of like Andy Griffith you know the operator would ring up [Laughter] but very uninteresting things about sunburst ad all that had to do with town of canton already there but being very small and just a country town no industry or anything you know it was just a little country town but champion and company not only town of canton but the whole county and WNC really. And all of the byproducts you know what I mean, as the company grew over the years and the suppliers of the machinery and people grew up getting paychecks from champion and go to Asheville and spend it or drink [laughter] you know vacations, I mean you know it’s a greater thing than you think about and of course the coal 12 Wayne Carson mining areas and the wood cutters and farmers they was able to cut wood and all kinds of things. JS: Well that helps a lot. WC: Have you about run out? JS: Just about we got a few more minutes so earlier you mentioned the union and, in my studies, and I found that with Reuben B as you call him you know he seemed to be a good mill boss and he fighted for the workers and things like that. And the union wasn’t, the union didn’t have a lot of backing like in the textile mills and other things like that have so there wasn’t as much need for the workers to want the union to come in. So, when did the union show up? WC: The exact day I can’t remember but it was maybe 63 or 64 when it was voted in and I was a young employee worked under non-union and the company followed it and I don’t blame them. I didn’t vote for the union although I didn’t fight against it. And it got in and I joined the union people voted them in. it worked good and we never as of yet hadn’t had any strikes or no big, there’s a few things changed. It got into more of kind of progression things. In other words, some of the old ways of before the union, not always but it worked somewhat like that what we was saying as me as an older person, blood is thicker than water. But lets talk about family and family showed more favoritism especially in the more lower jobs maybe and if the boss man liked you he might be working you more than an older employee, no big deal you know those things happened but no big gripe when the union came in its just a certain group wanted so they campaigned and campaigned and the company showed through letters and studies where other unions plans compared to our wages there. We were making as good or even more than other union plans in the same paper industries. Anyway It got in and we got a little raise and over the years what you done every few years you negotiated on this that and the other and they talked about it and argued about it and presented a contract and you either voted or not and I know over the years a few things were turned down and get down to the tension, one more vote, vote strike or accepted so far it never struck and I’m glad of it, I don’t think you gain anything. And over here we got [Inaudible] I don’t know all the things over in Brevard but those people in my opinion, this is my opinion [laugher] JS: Okay that’s all right. WC: they cut their own throat and the company claimed they couldn’t run of course they’re not and I would rather work at a place for 10 dollars an hour and have a job than work for 15 dollars and they was making I think more than that and I would rather take a cut in pay and have a job than not have one. JS: That’s right now Acousta is out of there, its not there anymore. WC: Anyway that’s I cant answer for that it doesn’t make any sense but that whole big trouble over the years with the union and in the last few years even in America the union has faded 13 Wayne Carson away from what it once was and it was the big man with the big stick that has the manufacturer over his knee and of course there’s a lot of corruption in the union.

Object

Object’s are ‘parent’ level descriptions to ‘children’ items, (e.g. a book with pages).

-

Jeff Seymour interviews Wayne Carson on November 21, 2002. Wayne Carson (born 1939), a Canton local who later moved to Buncombe County, worked in the Champion paper mill for 39 years. Carson discusses his experience from the new employee stage of his carrer to becoming a retiree. He spent most of his career in the chemistry department, and describes the ingredients needed to process paper. Additionally, he talks about the history of the logging industry, the transformation of the surrounding landscape, and economics of the industry. He experienced the paper mill downsizing operations and the introduction of a union.

-