Western Carolina University (20)

View all

- Canton Champion Fibre Company (2308)

- Cherokee Traditions (293)

- Civil War in Southern Appalachia (165)

- Craft Revival (1942)

- Great Smoky Mountains - A Park for America (2767)

- Highlights from Western Carolina University (430)

- Horace Kephart (941)

- Journeys Through Jackson (154)

- LGBTQIA+ Archive of Jackson County (26)

- Oral Histories of Western North Carolina (314)

- Picturing Appalachia (6772)

- Stories of Mountain Folk (413)

- Travel Western North Carolina (160)

- Western Carolina University Fine Art Museum Vitreograph Collection (129)

- Western Carolina University Herbarium (92)

- Western Carolina University: Making Memories (708)

- Western Carolina University Publications (2283)

- Western Carolina University Restricted Electronic Theses and Dissertations (146)

- Western North Carolina Regional Maps (71)

- World War II in Southern Appalachia (131)

University of North Carolina Asheville (6)

View all

- Allanstand Cottage Industries (62)

- Appalachian National Park Association (53)

- Bennett, Kelly, 1890-1974 (1388)

- Berry, Walter (76)

- Brasstown Carvers (40)

- Carver, George Washington, 1864?-1943 (26)

- Cathey, Joseph, 1803-1874 (1)

- Champion Fibre Company (233)

- Champion Paper and Fibre Company (297)

- Cherokee Indian Fair Association (16)

- Cherokee Language Program (22)

- Crowe, Amanda (40)

- Edmonston, Thomas Benton, 1842-1907 (7)

- Ensley, A. L. (Abraham Lincoln), 1865-1948 (275)

- Fromer, Irving Rhodes, 1913-1994 (70)

- George Butz (BFS 1907) (46)

- Goodrich, Frances Louisa (120)

- Grant, George Alexander, 1891-1964 (96)

- Heard, Marian Gladys (60)

- Kephart, Calvin, 1883-1969 (15)

- Kephart, Horace, 1862-1931 (313)

- Kephart, Laura, 1862-1954 (39)

- Laney, Gideon Thomas, 1889-1976 (439)

- Masa, George, 1881-1933 (61)

- McElhinney, William Julian, 1896-1953 (44)

- Niggli, Josephina, 1910-1983 (10)

- North Carolina Park Commission (105)

- Osborne, Kezia Stradley (9)

- Owens, Samuel Robert, 1918-1995 (11)

- Penland Weavers and Potters (36)

- Roberts, Vivienne (15)

- Roth, Albert, 1890-1974 (142)

- Schenck, Carl Alwin, 1868-1955 (1)

- Sherrill's Photography Studio (2565)

- Southern Highland Handicraft Guild (127)

- Southern Highlanders, Inc. (71)

- Stalcup, Jesse Bryson (46)

- Stearns, I. K. (213)

- Thompson, James Edward, 1880-1976 (226)

- United States. Indian Arts and Crafts Board (130)

- USFS (683)

- Vance, Zebulon Baird, 1830-1894 (1)

- Weaver, Zebulon, 1872-1948 (58)

- Western Carolina College (230)

- Western Carolina Teachers College (282)

- Western Carolina University (1794)

- Western Carolina University. Mountain Heritage Center (18)

- Whitman, Walt, 1819-1892 (10)

- Wilburn, Hiram Coleman, 1880-1967 (73)

- Williams, Isadora (3)

- Cain, Doreyl Ammons (0)

- Crittenden, Lorraine (0)

- Rhodes, Judy (0)

- Smith, Edward Clark (0)

- Appalachian Region, Southern (2399)

- Asheville (N.C.) (1917)

- Avery County (N.C.) (26)

- Blount County (Tenn.) (161)

- Buncombe County (N.C.) (1671)

- Cherokee County (N.C.) (283)

- Clay County (N.C.) (555)

- Graham County (N.C.) (233)

- Great Smoky Mountains National Park (N.C. and Tenn.) (510)

- Haywood County (N.C.) (3522)

- Henderson County (N.C.) (70)

- Jackson County (N.C.) (4692)

- Knox County (Tenn.) (25)

- Knoxville (Tenn.) (12)

- Lake Santeetlah (N.C.) (10)

- Macon County (N.C.) (420)

- Madison County (N.C.) (211)

- McDowell County (N.C.) (39)

- Mitchell County (N.C.) (132)

- Polk County (N.C.) (35)

- Qualla Boundary (981)

- Rutherford County (N.C.) (76)

- Swain County (N.C.) (2113)

- Transylvania County (N.C.) (247)

- Watauga County (N.C.) (12)

- Waynesville (N.C.) (73)

- Yancey County (N.C.) (72)

- Aerial Photographs (3)

- Aerial Views (60)

- Albums (books) (4)

- Articles (1)

- Artifacts (object Genre) (228)

- Bibliographies (1)

- Biography (general Genre) (2)

- Cards (information Artifacts) (38)

- Clippings (information Artifacts) (191)

- Crafts (art Genres) (622)

- Depictions (visual Works) (21)

- Design Drawings (1)

- Drawings (visual Works) (184)

- Envelopes (73)

- Facsimiles (reproductions) (1)

- Fiction (general Genre) (4)

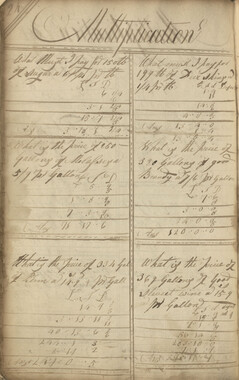

- Financial Records (12)

- Fliers (printed Matter) (67)

- Glass Plate Negatives (381)

- Guidebooks (2)

- Internegatives (10)

- Interviews (812)

- Land Surveys (102)

- Letters (correspondence) (1013)

- Manuscripts (documents) (619)

- Maps (documents) (177)

- Memorandums (25)

- Minutes (administrative Records) (59)

- Negatives (photographs) (5835)

- Newsletters (1285)

- Newspapers (2)

- Occupation Currency (1)

- Paintings (visual Works) (1)

- Pen And Ink Drawings (1)

- Periodicals (193)

- Personal Narratives (10)

- Photographs (12976)

- Plans (maps) (1)

- Poetry (7)

- Portraits (1960)

- Postcards (329)

- Programs (documents) (151)

- Publications (documents) (2237)

- Questionnaires (65)

- Scrapbooks (282)

- Sheet Music (2)

- Slides (photographs) (402)

- Songs (musical Compositions) (2)

- Sound Recordings (796)

- Specimens (92)

- Speeches (documents) (15)

- Tintypes (photographs) (8)

- Transcripts (322)

- Video Recordings (physical Artifacts) (23)

- Vitreographs (129)

- Text Messages (0)

- A.L. Ensley Collection (275)

- Appalachian Industrial School Records (7)

- Appalachian National Park Association Records (336)

- Axley-Meroney Collection (2)

- Bayard Wootten Photograph Collection (20)

- Bethel Rural Community Organization Collection (7)

- Blumer Collection (5)

- C.W. Slagle Collection (20)

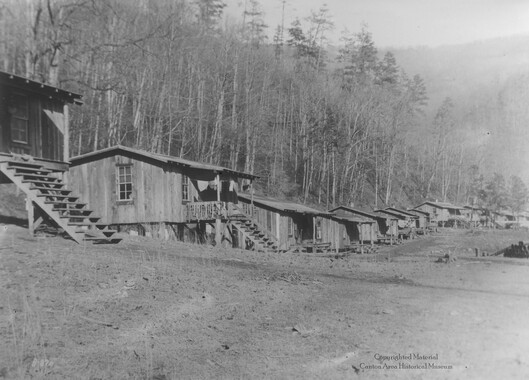

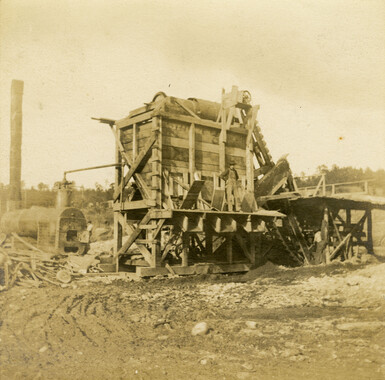

- Canton Area Historical Museum (2110)

- Carlos C. Campbell Collection (282)

- Cataloochee History Project (65)

- Cherokee Studies Collection (4)

- Daisy Dame Photograph Album (5)

- Daniel Boone VI Collection (1)

- Doris Ulmann Photograph Collection (112)

- Elizabeth H. Lasley Collection (1)

- Elizabeth Woolworth Szold Fleharty Collection (4)

- Frank Fry Collection (95)

- George Masa Collection (173)

- Gideon Laney Collection (452)

- Hazel Scarborough Collection (2)

- Hiram C. Wilburn Papers (28)

- Historic Photographs Collection (236)

- Horace Kephart Collection (861)

- Humbard Collection (33)

- Hunter and Weaver Families Collection (1)

- I. D. Blumenthal Collection (4)

- Isadora Williams Collection (4)

- Jesse Bryson Stalcup Collection (47)

- Jim Thompson Collection (224)

- John B. Battle Collection (7)

- John C. Campbell Folk School Records (80)

- John Parris Collection (6)

- Judaculla Rock project (2)

- Kelly Bennett Collection (1407)

- Love Family Papers (11)

- Major Wiley Parris Civil War Letters (3)

- Map Collection (12)

- McFee-Misemer Civil War Letters (34)

- Mountain Heritage Center Collection (4)

- Norburn - Robertson - Thomson Families Collection (44)

- Pauline Hood Collection (7)

- Pre-Guild Collection (2)

- Qualla Arts and Crafts Mutual Collection (12)

- R.A. Romanes Collection (681)

- Rosser H. Taylor Collection (1)

- Samuel Robert Owens Collection (94)

- Sara Madison Collection (144)

- Sherrill Studio Photo Collection (2558)

- Smoky Mountains Hiking Club Collection (616)

- Stories of Mountain Folk - Radio Programs (374)

- The Reporter, Western Carolina University (510)

- Venoy and Elizabeth Reed Collection (16)

- WCU Gender and Sexuality Oral History Project (32)

- WCU Mountain Heritage Center Oral Histories (25)

- WCU Oral History Collection - Mountain People, Mountain Lives (71)

- WCU Students Newspapers Collection (1744)

- Western North Carolina Tomorrow Black Oral History Project (69)

- William Williams Stringfield Collection (2)

- Zebulon Weaver Collection (109)

- African Americans (390)

- Appalachian Trail (35)

- Artisans (521)

- Cherokee art (84)

- Cherokee artists -- North Carolina (10)

- Cherokee language (21)

- Cherokee pottery (101)

- Cherokee women (208)

- Church buildings (167)

- Civilian Conservation Corps (U.S.) (110)

- College student newspapers and periodicals (1830)

- Dams (103)

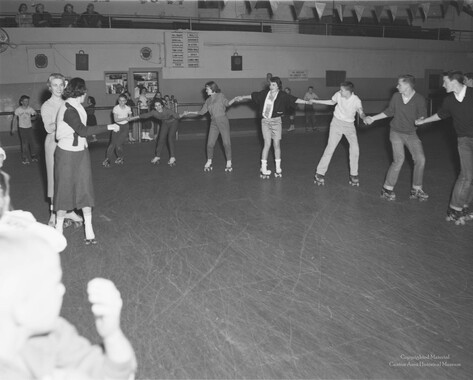

- Dance (1023)

- Education (222)

- Floods (61)

- Folk music (1015)

- Forced removal, 1813-1903 (2)

- Forest conservation (220)

- Forests and forestry (921)

- Gender nonconformity (4)

- Great Smoky Mountains National Park (N.C. and Tenn.) (181)

- Hunting (38)

- Landscape photography (10)

- Logging (103)

- Maps (84)

- Mines and mineral resources (8)

- North Carolina -- Maps (18)

- Paper industry (38)

- Postcards (255)

- Pottery (135)

- Railroad trains (71)

- Rural electrification -- North Carolina, Western (3)

- School integration -- Southern States (2)

- Segregation -- North Carolina, Western (5)

- Slavery (5)

- Sports (452)

- Storytelling (245)

- Waterfalls -- Great Smoky Mountains (N.C. and Tenn.) (66)

- Weaving -- Appalachian Region, Southern (280)

- Wood-carving -- Appalachian Region, Southern (328)

- World War, 1939-1945 (173)

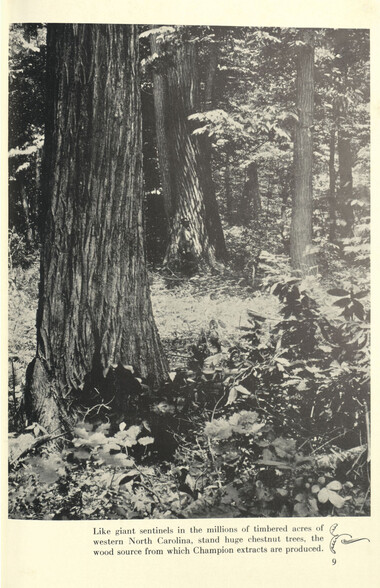

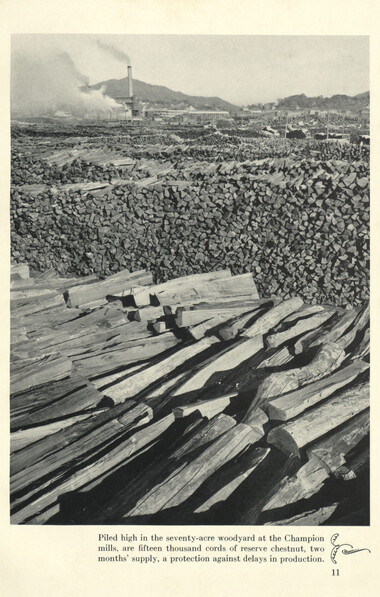

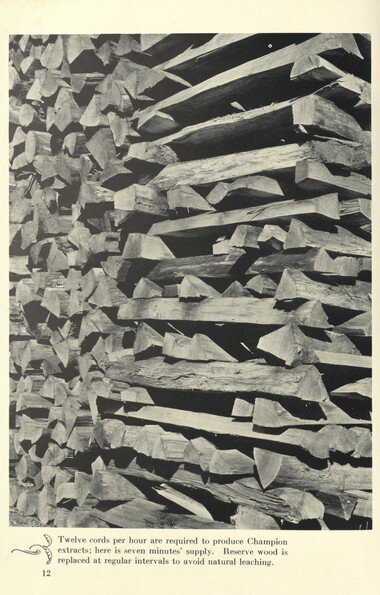

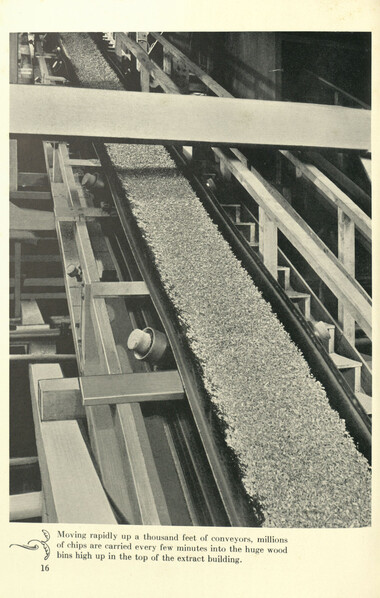

The story of chestnut extract

Item

Item’s are ‘child’ level descriptions to ‘parent’ objects, (e.g. one page of a whole book).

-

-

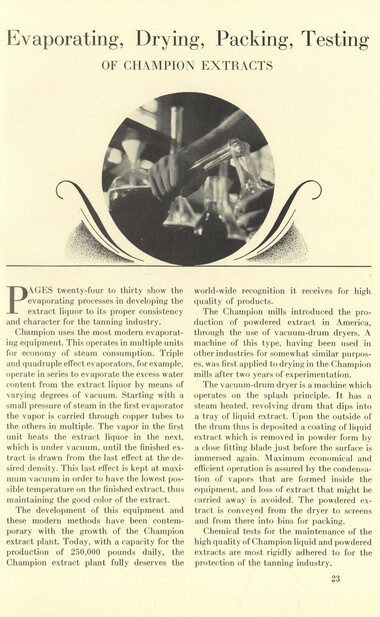

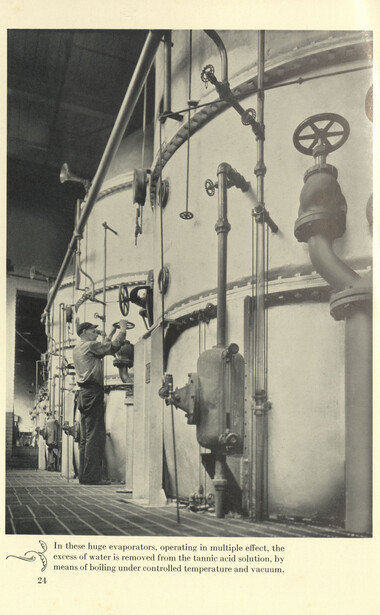

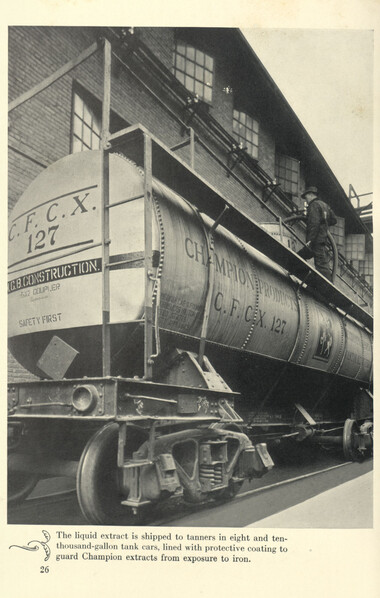

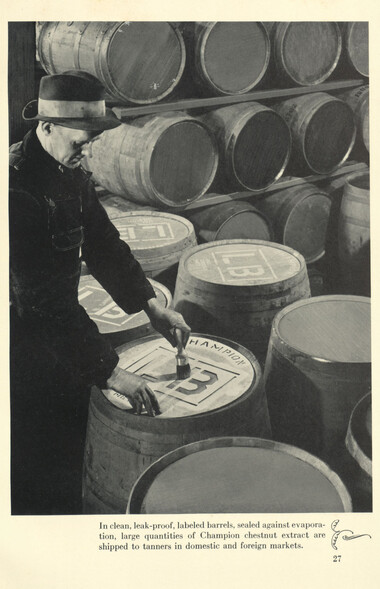

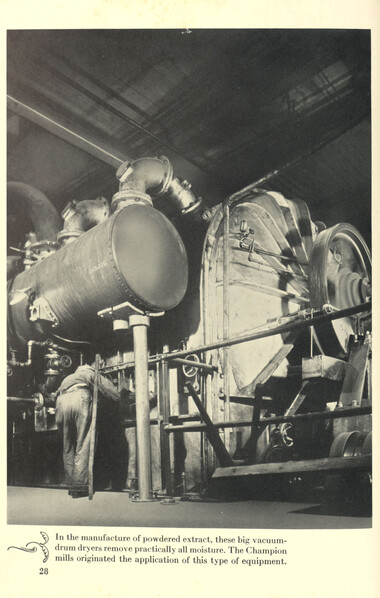

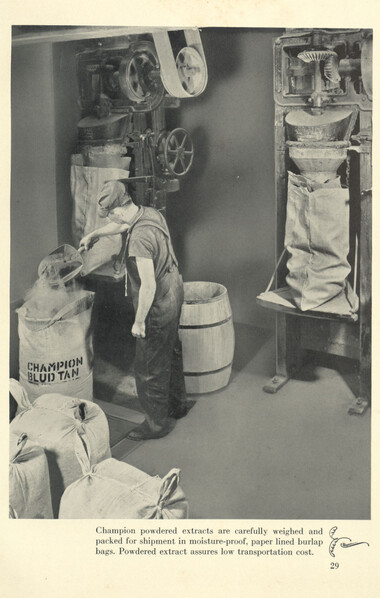

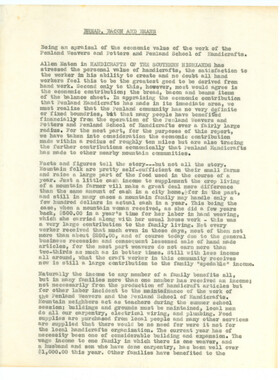

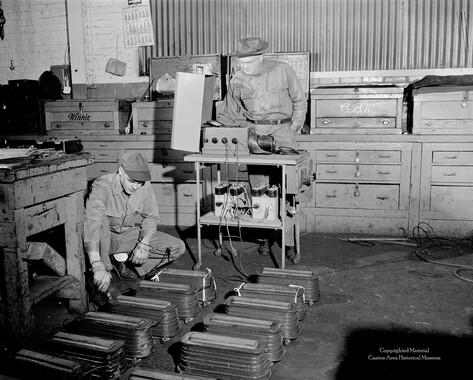

than any other material. Leather tanned with Chestnut Extract possesses high permanence being closely allied to the pure oak bark tannage. Champion chestnut extracts are produced in four grades, each of which is made available in either liquid or powdered form. These are designated as Standard, Light Standard, Bludtan and Melotan. Standard Extract is used for the tanning of heavy leather. It is also valuable as a re tanning agent for chrome tanned leather. In heavy leather, the glucoside of chestnut extract contributes the excellent qualities of weight, solidity and resistance to water, because of its natural acidity from its fermentable bodies. Light Standard extract offers the added advantage of use for tannages where lighter color is important. Bludtan, as its name implies, is decolorized with blood albumen. In this process the heavier and more insoluble tannins, as well as the darker coloring matters, are precipitated, producing a solution of mellow original tannin having the clearness of old wine. This grade is suitable for tannages which require a light color, or a mellow piece of leather. In either the liquid or powdered form it readily blends with any other tanning material. The powdered form dissolves in either hot water or hot liquid, does not lose any of its good qualities, and has the added advantage of saving freight cost. Melotan is of benefit to the tanner using pickled skins, such as sheep, calf, 8 pig, or even pickled splits. It is a special extract of the pyrogallol group and is produced in both liquid and powdered form. Besides being used alone as a straight tannage, or as a retannage for chrome tanned leathers, it is a fine acid mordant for use with basic dye- stuffs. Melotan can be substituted in any tanning process where quebracho, sumac or gambier are used. It produces a tight plump leather with full flank, excellent break and good tensile strength and will not turn red when exposed to sunlight. To provide the tanning industry with the greatest benefit from the purity and uniformity of Champion extracts the manufacturing processes are under the constant supervision of Champion's large technical control laboratory and well developed chemical production organization. The Champion extract plant is the largest single unit in the industry. Its combination with extensive pulp and paper making facilities makes available to its production of extract the highest degree of technical skill and protection to future production by a well organized research program. The maintenance of operation for the manufacture of extract by the Champion mills is assured for a maximum period of time by the availability of plentiful sources of raw material, and an organization that has the strength and power to continue as a reliable source for high value in all of its products.

Object

Object’s are ‘parent’ level descriptions to ‘children’ items, (e.g. a book with pages).

-

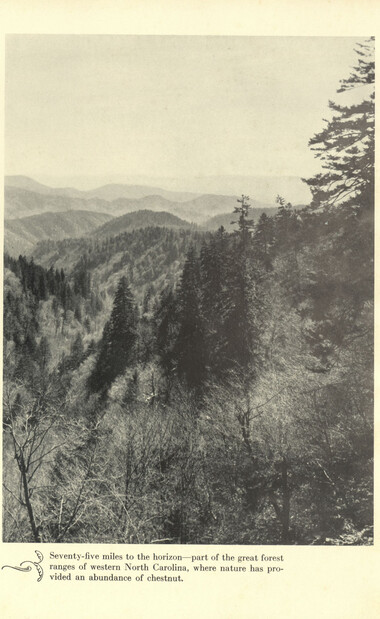

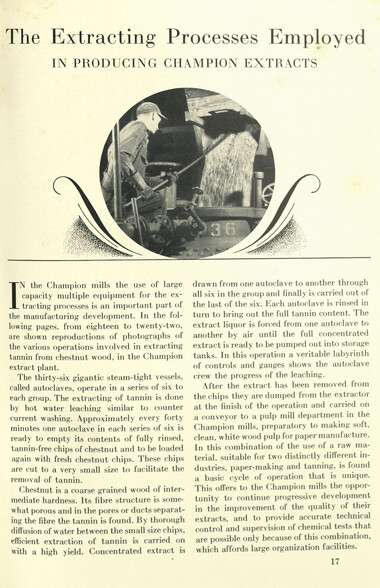

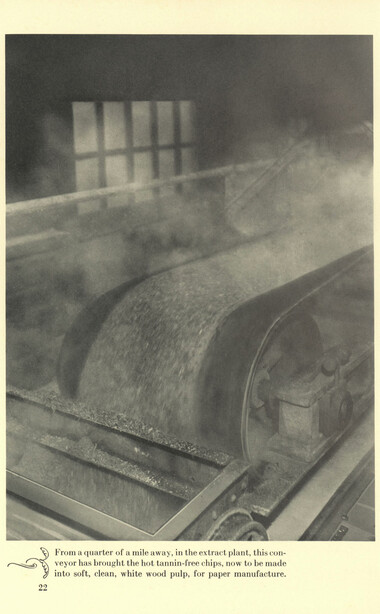

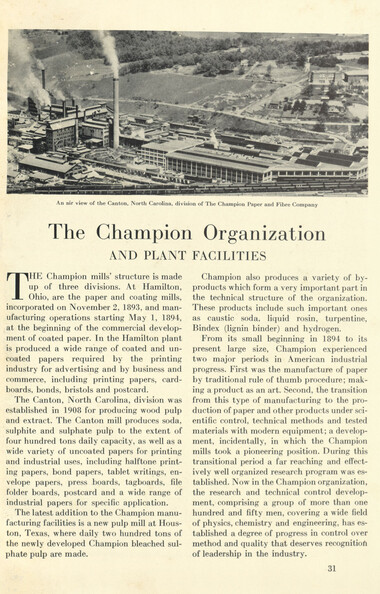

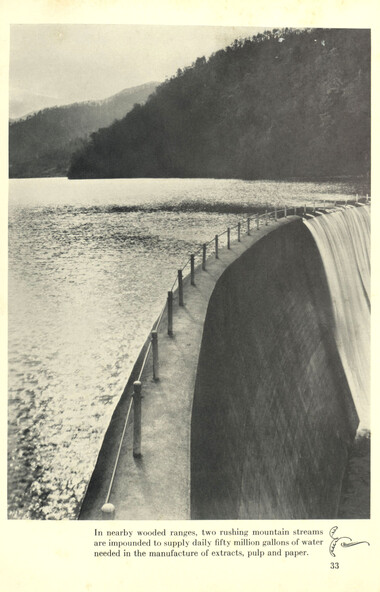

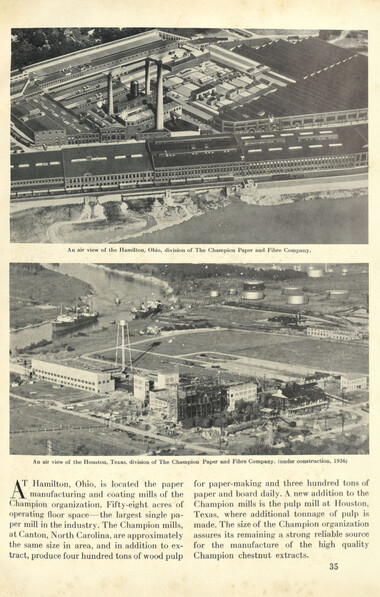

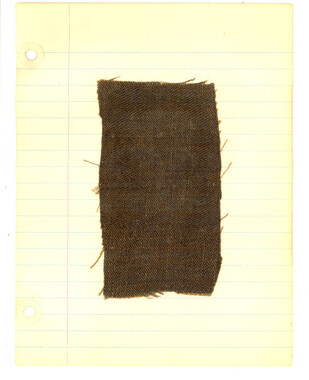

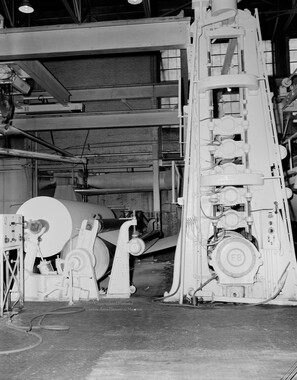

This 38 page book written in 1937 by Champion Paper and Fibre Company details the process of chestnut extract and includes many photographs. Chestnut trees provided a double use for Champion who pioneered, and had a patent on, the practice of extracting tannic acid and then using the sulphate method for pulping the wood chips to make paper. Champion was at one time the largest producer of 25% chestnut extract, exporting nationwide and to 12 countries. Production began in 1908 and halted in 1951 about 25 years after blight hit Western North Carolina killing off the chestnut trees.

-