Western Carolina University (21)

View all

- Canton Champion Fibre Company (2308)

- Cherokee Traditions (291)

- Civil War in Southern Appalachia (165)

- Craft Revival (1942)

- George Masa Collection (137)

- Great Smoky Mountains - A Park for America (2900)

- Highlights from Western Carolina University (422)

- Horace Kephart (941)

- Journeys Through Jackson (159)

- LGBTQIA+ Archive of Jackson County (85)

- Oral Histories of Western North Carolina (314)

- Picturing Appalachia (6797)

- Stories of Mountain Folk (413)

- Travel Western North Carolina (153)

- Western Carolina University Fine Art Museum Vitreograph Collection (129)

- Western Carolina University Herbarium (92)

- Western Carolina University: Making Memories (738)

- Western Carolina University Publications (2491)

- Western Carolina University Restricted Electronic Theses and Dissertations (146)

- Western North Carolina Regional Maps (71)

- World War II in Southern Appalachia (131)

University of North Carolina Asheville (6)

View all

- Allanstand Cottage Industries (62)

- Appalachian National Park Association (53)

- Bennett, Kelly, 1890-1974 (1463)

- Berry, Walter (76)

- Brasstown Carvers (40)

- Carver, George Washington, 1864?-1943 (26)

- Cathey, Joseph, 1803-1874 (1)

- Champion Fibre Company (233)

- Champion Paper and Fibre Company (297)

- Cherokee Indian Fair Association (16)

- Cherokee Language Program (22)

- Crowe, Amanda (40)

- Edmonston, Thomas Benton, 1842-1907 (7)

- Ensley, A. L. (Abraham Lincoln), 1865-1948 (275)

- Fromer, Irving Rhodes, 1913-1994 (70)

- George Butz (BFS 1907) (46)

- Goodrich, Frances Louisa (120)

- Grant, George Alexander, 1891-1964 (96)

- Heard, Marian Gladys (60)

- Kephart, Calvin, 1883-1969 (15)

- Kephart, Horace, 1862-1931 (313)

- Kephart, Laura, 1862-1954 (39)

- Laney, Gideon Thomas, 1889-1976 (439)

- Masa, George, 1881-1933 (61)

- McElhinney, William Julian, 1896-1953 (44)

- Niggli, Josephina, 1910-1983 (10)

- North Carolina Park Commission (105)

- Osborne, Kezia Stradley (9)

- Owens, Samuel Robert, 1918-1995 (11)

- Penland Weavers and Potters (36)

- Roberts, Vivienne (15)

- Roth, Albert, 1890-1974 (142)

- Schenck, Carl Alwin, 1868-1955 (1)

- Sherrill's Photography Studio (2565)

- Southern Highland Handicraft Guild (127)

- Southern Highlanders, Inc. (71)

- Stalcup, Jesse Bryson (46)

- Stearns, I. K. (213)

- Thompson, James Edward, 1880-1976 (226)

- United States. Indian Arts and Crafts Board (130)

- USFS (683)

- Vance, Zebulon Baird, 1830-1894 (1)

- Weaver, Zebulon, 1872-1948 (58)

- Western Carolina College (230)

- Western Carolina Teachers College (282)

- Western Carolina University (2008)

- Western Carolina University. Mountain Heritage Center (18)

- Whitman, Walt, 1819-1892 (10)

- Wilburn, Hiram Coleman, 1880-1967 (73)

- Williams, Isadora (3)

- Cain, Doreyl Ammons (0)

- Crittenden, Lorraine (0)

- Rhodes, Judy (0)

- Smith, Edward Clark (0)

- Appalachian Region, Southern (2940)

- Asheville (N.C.) (1944)

- Avery County (N.C.) (26)

- Blount County (Tenn.) (195)

- Buncombe County (N.C.) (1680)

- Cherokee County (N.C.) (283)

- Clay County (N.C.) (556)

- Graham County (N.C.) (238)

- Great Smoky Mountains National Park (N.C. and Tenn.) (525)

- Haywood County (N.C.) (3571)

- Henderson County (N.C.) (70)

- Jackson County (N.C.) (4919)

- Knox County (Tenn.) (35)

- Knoxville (Tenn.) (13)

- Lake Santeetlah (N.C.) (10)

- Macon County (N.C.) (421)

- Madison County (N.C.) (216)

- McDowell County (N.C.) (39)

- Mitchell County (N.C.) (135)

- Polk County (N.C.) (35)

- Qualla Boundary (982)

- Rutherford County (N.C.) (78)

- Swain County (N.C.) (2185)

- Transylvania County (N.C.) (270)

- Watauga County (N.C.) (12)

- Waynesville (N.C.) (86)

- Yancey County (N.C.) (72)

- Aerial Photographs (3)

- Aerial Views (60)

- Albums (books) (4)

- Articles (1)

- Artifacts (object Genre) (228)

- Bibliographies (1)

- Biography (general Genre) (2)

- Cards (information Artifacts) (38)

- Clippings (information Artifacts) (191)

- Copybooks (instructional Materials) (3)

- Crafts (art Genres) (622)

- Depictions (visual Works) (21)

- Design Drawings (1)

- Drawings (visual Works) (185)

- Envelopes (73)

- Exhibitions (events) (1)

- Facsimiles (reproductions) (1)

- Fiction (general Genre) (4)

- Financial Records (12)

- Fliers (printed Matter) (67)

- Glass Plate Negatives (381)

- Guidebooks (2)

- Internegatives (10)

- Interviews (815)

- Land Surveys (102)

- Letters (correspondence) (1013)

- Manuscripts (documents) (618)

- Maps (documents) (177)

- Memorandums (25)

- Minutes (administrative Records) (59)

- Negatives (photographs) (6090)

- Newsletters (1290)

- Newspapers (2)

- Notebooks (8)

- Occupation Currency (1)

- Paintings (visual Works) (1)

- Pen And Ink Drawings (1)

- Periodicals (193)

- Personal Narratives (10)

- Photographs (12976)

- Plans (maps) (1)

- Poetry (5)

- Portraits (4568)

- Postcards (329)

- Programs (documents) (181)

- Publications (documents) (2443)

- Questionnaires (65)

- Relief Prints (26)

- Sayings (literary Genre) (1)

- Scrapbooks (282)

- Sheet Music (2)

- Slides (photographs) (402)

- Songs (musical Compositions) (2)

- Sound Recordings (796)

- Specimens (92)

- Speeches (documents) (18)

- Tintypes (photographs) (8)

- Transcripts (322)

- Video Recordings (physical Artifacts) (23)

- Text Messages (0)

- A.L. Ensley Collection (275)

- Appalachian Industrial School Records (7)

- Appalachian National Park Association Records (336)

- Axley-Meroney Collection (2)

- Bayard Wootten Photograph Collection (20)

- Bethel Rural Community Organization Collection (7)

- Blumer Collection (5)

- C.W. Slagle Collection (20)

- Canton Area Historical Museum (2110)

- Carlos C. Campbell Collection (462)

- Cataloochee History Project (64)

- Cherokee Studies Collection (4)

- Daisy Dame Photograph Album (5)

- Daniel Boone VI Collection (1)

- Doris Ulmann Photograph Collection (112)

- Elizabeth H. Lasley Collection (1)

- Elizabeth Woolworth Szold Fleharty Collection (4)

- Frank Fry Collection (95)

- George Masa Collection (173)

- Gideon Laney Collection (452)

- Hazel Scarborough Collection (2)

- Hiram C. Wilburn Papers (28)

- Historic Photographs Collection (236)

- Horace Kephart Collection (861)

- Humbard Collection (33)

- Hunter and Weaver Families Collection (1)

- I. D. Blumenthal Collection (4)

- Isadora Williams Collection (4)

- Jesse Bryson Stalcup Collection (47)

- Jim Thompson Collection (224)

- John B. Battle Collection (7)

- John C. Campbell Folk School Records (80)

- John Parris Collection (6)

- Judaculla Rock project (2)

- Kelly Bennett Collection (1482)

- Love Family Papers (11)

- Major Wiley Parris Civil War Letters (3)

- Map Collection (12)

- McFee-Misemer Civil War Letters (34)

- Mountain Heritage Center Collection (4)

- Norburn - Robertson - Thomson Families Collection (44)

- Pauline Hood Collection (7)

- Pre-Guild Collection (2)

- Qualla Arts and Crafts Mutual Collection (12)

- R.A. Romanes Collection (681)

- Rosser H. Taylor Collection (1)

- Samuel Robert Owens Collection (94)

- Sara Madison Collection (144)

- Sherrill Studio Photo Collection (2558)

- Smoky Mountains Hiking Club Collection (616)

- Stories of Mountain Folk - Radio Programs (374)

- The Reporter, Western Carolina University (510)

- Venoy and Elizabeth Reed Collection (16)

- WCU Gender and Sexuality Oral History Project (32)

- WCU Mountain Heritage Center Oral Histories (25)

- WCU Oral History Collection - Mountain People, Mountain Lives (71)

- WCU Students Newspapers Collection (1923)

- Western North Carolina Tomorrow Black Oral History Project (69)

- William Williams Stringfield Collection (2)

- Zebulon Weaver Collection (109)

- African Americans (390)

- Appalachian Trail (35)

- Artisans (521)

- Cherokee art (84)

- Cherokee artists -- North Carolina (10)

- Cherokee language (21)

- Cherokee pottery (101)

- Cherokee women (208)

- Church buildings (190)

- Civilian Conservation Corps (U.S.) (111)

- College student newspapers and periodicals (2012)

- Dams (108)

- Dance (1023)

- Education (222)

- Floods (61)

- Folk music (1015)

- Forced removal, 1813-1903 (2)

- Forest conservation (220)

- Forests and forestry (1197)

- Gender nonconformity (4)

- Great Smoky Mountains National Park (N.C. and Tenn.) (181)

- Hunting (46)

- Landscape photography (25)

- Logging (119)

- Maps (83)

- Mines and mineral resources (9)

- North Carolina -- Maps (18)

- Paper industry (38)

- Postcards (255)

- Pottery (135)

- Railroad trains (72)

- Rural electrification -- North Carolina, Western (3)

- School integration -- Southern States (2)

- Segregation -- North Carolina, Western (5)

- Slavery (5)

- Sports (452)

- Storytelling (243)

- Waterfalls -- Great Smoky Mountains (N.C. and Tenn.) (66)

- Weaving -- Appalachian Region, Southern (280)

- Wood-carving -- Appalachian Region, Southern (328)

- World War, 1939-1945 (173)

A History of Champion Papers, Chapter 4, The Research Story

Item

Item’s are ‘child’ level descriptions to ‘parent’ objects, (e.g. one page of a whole book).

-

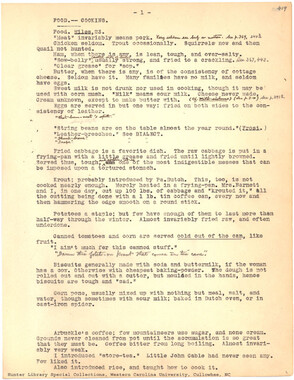

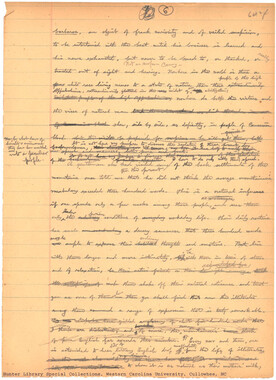

Chapter four of Corydon Bell's 1963 history of Champion Papers covers the research story. This 12 page chapter starts with how the research team was formed and tells the story of their first major task of creating all grades of coated paper. This chapter covers research done on various processes of papermaking within the plant and how the research practices evolved over time.

-

-

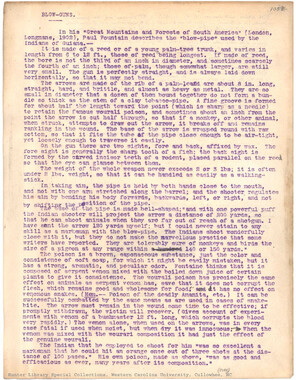

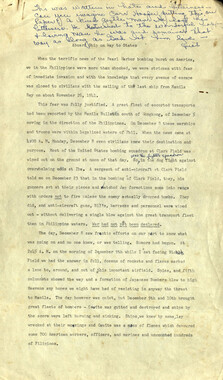

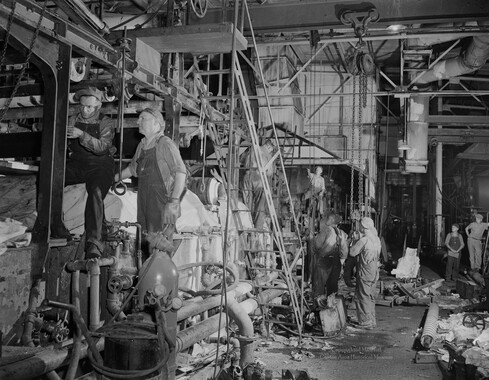

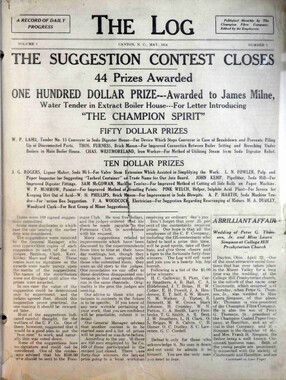

) 1) ~ THE R.ESEA.RCH STORY The So1ent1£1c Ageroach Not long after the CiVil War a patent examiner is said to have made a remarkable recommendation. Ue proposed to the On1ted States Governmant that the Papent Office be discontinued, because all practical improvements in science and theohnology that. could possible be achieved had &beady been a.eoomplubed.~:! Merely a obs.oey glance at tho diversity or technological achievements that crowd our modern world testit,y to hov completelY thia unimaginative gentleman or a century ago underestimated the resources ot the hum.an mind. Today, in an environment or increasing competition. ao1ent1£1o research and invention constitute the lite blood. or business and 1ndustey. The paper industey is no exception to the pressing need or oonatantl\1 :l.mproving the value and quality or established products and or broadening produoti'h tields through experiment and origination. In the earl3' Tears of pulp and paper zuking a.t Champion, each m1l.l. op. entecl, tor the most part, by m.ethods evolved trom long established practices. As tilae pUsed• however, the questions ot "how" and 1twhy• called tor more accurate and spec1£1o aruswera. As a reault.. some SO ,_ara ago, processes began to be aubjeoted to searoh1ng sorut1r,-. This work required an organi• cation eapec~ equipped and qualified to carr.y on these enquiries. What evolved to satiety this need was the paper chemist's laboratory. The tirst small mill laboratories were alender~ started b.1 a ohemical technician, a paper engineer, and perhaps an assistant or two. These groups, that grappled with uporopping technical pl'Oblems, and that also kept an analytical eye on the matter or variables 1n da;r•to-day production, were 2) the to runn rs of Chal!lpion' Depart.Dlent or Research and inee • he year 1951, thi organi tio , which during a q er of a o nt'IU'7 was to oo tr1bute conspicuoualy to the oompan,y1a prot rity, h d expanded to include about SO sci ntista and as man,y technioiana. The to or Champion research begin ey shortly 'b&to 1926, when tin rJhite. once the ohiet support or all high s behaving ~ on he co tars. To be pec1t1c, t a t.erial wa prod o unma ge. ab]3 thick oo tinge. The al tha. t entered into its composi t on was sus-peoted o£ being the culprit. ianag n pro ptly pped ~p the probl m and t rred it to the DuPont Compan,y, supplier or tho &lUll. 'lhen everal attempts to remeey- the situation taUed, DuPont t.1.nally sent out top •troubl .. hooters,• Donald B. Bradner, to lllake an xhaustive investigation. It took Brad r but a short time to solve the problem once and tor aU. h1 exhibition or almost gical ett1o1enc,r 80 deoply press V<-1 E t{ I [ , I tt 1 f.. ion ana.geent that J)lPont soon lost a key man. On 1 , 1 6, Don adner bee Champion • s ti st Director of Research. thin a tew nt Dr dnor ad gathered around h1rrl the D'lOleUI or what w&I!J to become on or • Knapp, ter nton, Vino X..ude • and Charles Milligan. his aoqua1n nee with m1ll tac1l1t1es 1 Doo11 Milligan earned eomewhat or a legendar.y eputation when bis pq ohellk got lo t 1n a bleach beater, and when c t tails bee ca~ht in cast c ting drum and he o suall7 back d out of t ga~ment , letting it disappear into the machinery. • • J . (" nte" ) r:y, who eventually b came Director Ge ral. ot Rase h, joined t. e gro p thin a year. One of the 1nit1al und rt kings ot th new depar nt wa to urv y all ) ) 3) operations in the M1U in order to rough17 determine process coats. and to discover areas in whioh profitable improvement or proceas&l could be t£Ch1e'9'ed.. A. result of tbit inVGst.igation was that the a.ttention ot tte.. search beoar.te tooua~c:l on the Hamilton coating tldJ.l., and for some 1e&rtl outing cOMpOsition and eoatins prooe~Seea eoutituted the on1of ooncem of the pooup. Not ol'll.y wer. coating opera.tiolUI meohanioallJimproved, bUt ooati.n$e ot higer quaU.ty w~ attained th~ugh aoient1ti ~ standardizing coatintt forn..~s. For e:a.srtpla• 'rl.sooa1ty and pH value oontNlo weJ<~e introduced. Viaoosit;r o£ a ooat.ins matet"ial has to do with i\s relativ-e flow over the surface ot the paper to which it 1a appl.1eda and pH va.lu.e raters to the aoidity or alkalinity of the coating soluM.on 1tselt1 nd is i'alporiant to its oheidoal. beha'Vior. An investigation or the adheaiVIt strength ot varloua coating tormulat led to the development of the ntack" tester. By accurately controlling ooati.ng stl"eftith, it beome poas1bl.e to reduce excessive arno\ll'lts of adhesive i'ol'!llorl.T thought necessuy to prevent •p1ok• 1ng,• wh1oh 1s a term ueBd to des01"1bo the a.otion of inked type or plates on a pttintin$ press that tends to pull away from the paper flakes of coating tba.t conta1ns too little adheaift• 1'he J~esults or th.1s reaearab pro• jeot was not only a sa.v:i.ng 1n adhes11'e u.tel"Ul.• bUt also a pat improvement in tb.e printabUity of all grades ot Cha!Upi·=>n coated papeH. £&81{ 29&\W U inv~mt!J! Alaoat ever,yone on the statt ot Research had something to do with the de-Mlopment and. 'Qltimate euocees of what is considered Oh&mpion•s greatest. ocntl"ibution to the coated paper .tieldt a cast coated pa.per knOwn by the tr~rk name or Kromekote. The preparation of oaat coated paper re-s bles SOl'llewhat the process used by' photographer• 1n finishing glossy pr1nta. . In that process, wet photograpb1o prints are place face down on ) 4) a dust-tree, highly pol bed 11fel"l"'typo• tin or on a oath chl"'m plated surface. W1th a rubber blade the water is eque ed trom between the printa and the et.l. t.Jhen the prints have driGcl and are lU'ted from the plate, they exhibit tha sam 8l'llOOth, gloas7 t'1n1sh as the etal. Applyins this principle to a t'reshly coated sheet ot pa r vould se a simple prooedur ; but undried coated pa.pe1' ha a wicked tendency to act. ere to metal, &a !rustrated Research rtlen at Champion d1 oovet'e<l. Year of patient experiment&tion were consumed in e!forta to overoo e this ditficulty. It the resUlts or some or tho experimental err rts had been even 10~ less rewa ing, the ohanoes tor oontinuing th project would h ve bean d indeed. In t , however. the mal.l-ae&le laboratoey a were conaide d euooesstul. enough to be transferred to a six-toot. chrond.U.'ll<oilplated dl"\IIJ in the "a.ul Pen. 1 ll'ay after day, lor years, large-soa.le experimental wrk conti.'lluod on the drum. Finally, in 1929, a basic pa nt coYer both process and product was issued to Champion. Co eroially aoo ptable paper wa.a eventual.ly naade 1n th tt~ Pen• triala, and the operation was at last turned over to t. e Production De. partzn&nt 1n 1942, lthough ltese roh continued to aid in 1lllprov1ng t..1e pro. duct and the ohanios o! the prooea • A later develo nt was t t ot producing out coated paper 1n colors s Coloroast Kro kote was amounoed in pr1l 19.51. In oonneotion ating, pion aper Compaq. Ltd. organ1 a oompa su idia.ey on ebruar;y J. 954, at ce rland, tor expodi 1ng !orei n • and to 11 eneing Cbarapio unuf'aoturing proc sses in tor o tr es • Th cast. oo ting p:rooees was 11ceneed to Belgian t in 19.54. to a paper mUl in G t itain in 19.56, a.nd to a per r Japan 19.57. ) $) -r•t&.nd~ Tho beautitul wtd.te color and lQli' coat ot calo:itull ca~bonate, pf'OYi.ded as a. by-product 'by the s.ap Wut171 pl'Olltpted experimenta:tiori With Pl'<>otor and Gat'l'ible •s 11slwls••" This material wu delivered t.o the Hamilton coating m:Ul. 1n tank cars. and became th$ nourse and oussGd•attt or a n'tUilber ot Researohere who struggled to make a. workable fl.Uer ot' ooaUna p1pient .fJl"()m 1t. AlthoUgh th6 •sluds~• nel'e:r p~uoed Whole-b&Arter.t S\o0$ss, 1\s t.rialo Clid lead to the de't&lopment ot Cbampicm*s .ovn ca.lcium carbonate tJ!o• lime and nu.e gaa, a. mate:rieJ. that came to known a.s Calcote. It wa.s anoth.e:r stoey" ot tedious experimenta..tiont this tittle, to discover the pJll'>ptl' oouditiona of manufacture to pro'V'ide a product. of the de.s1S"ed particle fin and with acceptable pl'irlting pi"'perties. Despite all ot' the teob:n1cal. h~ dles ·to be j\lm.pe4, Cal4ote eventUt.ll1 went into suoeesstul MnufaotUl"G at both the .HOh1o and 1'~tUa DiVisions. In the days ot the Great Depression, ba.ok in the 19))a1 high grade coated paper became almoet a drug on the ~rket. Lookinc critic~ at the ~ tpb-11\1 a1t\lat:J.on.1 Don BN.dner said aomethins lik-e t h1•• "Wbt can't W#J Jllake a pe.per that would be a tort. ot 1n.\e%'1tle4iate between ooated paper and uncoated papers a paper that would print well and have aommat the appearance ot coated paper, but still could be lWlufa.otured at & M.gher apeod on a paper maohintt eo that :1t could be cheaply p~uced and ~pture some of the :u.gazin& marke\ t" It was a fresh idea, and. ever;rone in Research was enthUBiaati<h Firat &Xpe~"hlenta undertaken consisted ot appl.yins an unusually he•Y.Y deposit of coating campo ition to a wb ot paper in the above the f'1bree was scraped ott with a blade, thua pro'V'ic:l1Jl& a aurtace- ) ) 6) tUled, o.:r semi-coated pe.peP. AI is tr\e ld.tb. tb.e tno1p1ent tri.als ot mo•t nw proceeset.t, there wre imllediato dit.t'toultiea., On tht: one band, it was not eas7 to apply eX0&$11.V. coat.lng to· a thb, we\. fl!"agile web of p&ptJJ'l and. on the ot.hol.' band..,. the paper mao~• men, proud ot the ole~ss of t.b.eir m1U, were tar from M1JP1 abtnat hartr:l; theb' driers and felts toul&d with what they t«~ae.4 ttthat. lU\lq coating sturt •. • the Relt~a..oh.e:roa were not eui'.l.T tU.aeour:aged• however, They took theb eXper~nts ba.Qk to the ooatitll JfOOlll • and aob:te•• e(1 same ncceas on No. as <>O&tel" that had been fitted lt.lth spe.ciel drler dnms. ltl tact, a good raa:nr tons ot Naaelo were pJ'OduOI!l<l in tbis l~U~ll'nez.-., Complete suo®ss tball.7 was achieVed when the pApel" Jdll people cie... oided w ooope;ra.t.e oa the pl!"ojeot. With everyone detemittf.td to pool theit' skills, a ·l'Ufl ot aoeUent ae%!1'1.ooated pa.pl!lr wa.a made on a paper machine. Within a shot"t tiw.e th.a ql.Uility ot .this typs ot •took Rlli uproved as :t.t we disoovered. how to apply heaviel" and heaVier w1ghte of coating ma.t. erial. to the wet •b• Cbampl<Jn wu not tho only ~a:()tur.r in the indUftr; r WZ"ld.ng on tho probla ot per!e¢t.1ns a S\J.rta.oe•nlled paper • Con. aol1dated Paper ~Of developed the Massey eoa.ter du.rl.ng tile late 19,_• c and KimbeJ'k7·Cl.t4rk O&n$ bto the maohinQ.Ooating tuld &t a later date. The tuc~s• or t.be Ch&Mpion pl'Oduct accounted to some extent to.,. th• tleoision of management to o"ot a mill at Paaad en&• Texas, largely tor the produot~on of .wJ:t me.ga.zine paper. A United Stat-eo J?a.pent, No. 1.913,)29. was issuacl on June 6, 193.), covering the •ohino coating prooesa. A p.-ofit• bl.e sequel 'to the project has been in the tom or patonts througb.out the world, and the licensing or the prooose to sonia 20 manutaoturars in America and to 15 companies in 12 to:reigb oount.rias. ) ) 7) On tq X.FW,ghin& Sometime in 19,. ReseaJOCh too an investige.toey look into the supercalendering ot paper. Thi1 finishi.ng prooess oona1sts ot passing a web of paper betlfeen heated rolls in order to provide the stock with a un:if'OIJl• ~ smooth surta.ce. To obtain the most satisfactory twah 1n the superoal• ndering prc;oess, sol!le moisture is requiHd,. The traditional pactio• has been to equably distribute t.be moisture t."lrou.ghout the paper. As oonceive< l by Rese~h in its x ... Flni$b. procets, on.l.y the sutaoe or the paper is moistened, and the supe~endering is acco~plished betoro the moisture can p$netra~ into the body of the stock. :t.Finisbing bAs since given a much impJIOved a~aee t.o fUm7 mUlons ot pounds ot Champion product, both coated and uncoated. i•P!r wit,h s ;?~sence. Resea:roh is ttot without a to\eh .of the exotic and the blhrre .- Daring the late 1920s a New York publication called if.J.lzhoo Magagine becQe a at~ custOl!ler. A yet.r or two before the "peal ot pnhib1t1on in 19)), the sales department received a t~legram from the editors of the now detanot pel'iod1o&l tJking 1t Champion could supply a paper that smelled like wh1slq or gin. The idea was that when a l'ea.der oame to an appropt-U.te p]A.oe 1n the magacine; there would arise t:rom th-. pages the delightful arOD\& ot a apea.kea.sy bar". Qu.1t.w toaa.sonabl.y, this problem was plaa;,d in the lap ot Research. Certain chemical experts in the department decided that gin ottered the ost favorable chances tor success. ll$cause ot its delicate, highly dUu.ted a:romat1o ingredients. gin 1tselt would not produce the desired etteot when wedded to paper. Something synthetic would have to be attempted. Vax-ious experiments w1th extx-aot or juniper berries, vol.atUe oUa, and even turpentine wero made in the laboratopy, and at last what vas generaJ.l¥ ) ) 8) agreod upon as a '*real cinny smell* issued troll a beaker of liquid. •~hen t-o fNr. < t" il."" q ful 'l-...e,.. the concoction vas ma.gnit1ed to~*'a , application was made to paper with a spray gun in the %'eel room, which took on the diczying atmosphere or a dist1lleey. 'l'he paper in a weU sealed package was ahi;pad to 'BallYhqg. In a rev day's a telegram wa.s received from the magazine a 11Gi:n may- smell like that in Hamilton but rou sure couldn't get away with it in Now York." End or ·~rtmant. ~Old l)Mrf Worldng quietly behind the speotaoular cenaa ot Retearah, there were many men who oontribu.ted. their talenta to the auooess of the ahow. Among them were Fd. Warner, Senior Research Engineer, and Fred Boyer, Senior Patent Attorney. !bth retired from long and productive careers at Ham. ilton in October 1960. ria Warner spent marxr hours or oonoentrated effort at the draughting board. designing intrioa.te pieces ot equipment tor Ch&!llp. ion. Among his contributions to the coating area was the substitution or rollers tor the long .. used brushes on coating maehi.neth ne also de wloped much ot the JU.chinery" for cast coating 1n eooperation with General Reaeuoh. Fred Boyer. 'Whose job it was to protect the prooeasea a.nd equip:llent developed b;r Co.am.pion. was 1nstrumanta.l 1n o btain1ng some 1) pat-ents for th-e eor.tpaf\Y--not the simple task th&t one might irtlagine it to be. Researoh is Centralised The Gener l Research Group at Hamilton wu joined in 1949 by the Pulp and D.Y-Produota Group f'rom the Carolina Division. This group had ooen formally assembled in 1928 under the leadership of Phalti Lawrence, nd it had achieved particular recognition tor its work in improYing pulping processes and Cleaohins methode. ~11s tatr had also been responsible tor ) 9) the development of by-products such as t&ll oU, t&nrd.ng materials and turpentine. rheir most rewarding accomplishment w $ the research that made possible the production or a bright, strong bleached sulphate pulp from southern pina. It~was an achievement of even more importance than the double use o! chestnut wood, and rel'IUI.ins one of Champion•s 11f'irsts 1 ' in tho industry. rhere was at. one t:L"Ille some controversy about t 1a verity of c:1ampion' s statement of being first. in manufacturing wnite paper fro :southern pine. Of this • euben 1\obartson has some com ants : 11 rhe enforced abandonment ot reliance on spruce &de it necessary tor Champion' supervisory .forces to inten:sity and aaoelera.to tMir efforts to make pine fibre erve sa substitute for spruce. It was recogni&ed t.&t succes there was a matter of li.fe or death for thr~ enterpri o. th t ut.t grim st11llulus before us. naturally our very ~st efforts were put forth. fhe gr tifying results ware tnat not only was a stro ger and better fibrs produced, but that it was produced at costs very substantially below those that would have prevailed had we continued to use spruce as our basic pulp. wood. 11It has been stated repeatedly that Dr. Charles 1. erty, of the .lerty Laborator.1 at Savannah, was tne first ker or ~ ite P!E!r from pine in the ~outh , This statement is correct it newsprint is considered a ~ paPGr• It is not correct if it is intended to include wni p r of t e oo paper grades: because Champion's successful runs of paper made from pine oooked by t e krafy ethod and bleached to a full w. ite antedated the . rty production by na rly tan years. Hfhe unique feature ot Jr. arty's acoo plis nt was in the successful conversion o£ southern pina into usable groun~ in pite of tne pr •ence of ver.y troublesome quantities of resinous tter. n aking n sprint you do not use bleached pulp: you rely on t e natural color of t1e od for 10) the most part. Newsprint is unbleached pulp plus groundwood. When you use groundwood ade from pine you get all the resinous matter that ars in the stick right on tl'1e paper sheet, and this causes plenty of trouble . f~ctually, it is easier to . ko fine paper out of pine than it is to ake ne print. The e r1sinous materials created no serious difficulty .for Cha pion in the making of its ble chad kraft, as the action of the bleaching solutions re .. movod the r sins, or at least the greater percent ge of them." The bringing together of all research at Ha:n.ilton provided Charr1pion with an efficiently integrated department in which praotioal\1 all pha1es or paperma."< ing research could bo oa.rried on: from the chipping of wood to the evaluation of t.he finished proiuct. Detailed description of Research's multitold &COOMplio~~ents nnot b$ attempted here . A brief re um3, how v r, provides some idea or its varied performance; the developm nt of new productsa 1 • provement of product quality through engin oring design. new achines . new prooasse$, and instrur.I ntation that m11kee po sible ccurate and uto:natio control in many areas of manufacture; the introduction of tasting methods that led to improved formulas tor pulp nd for co ting material ; the evo-lution or cheaper and better r w materials, as well v uable by-products; and, over all, the achievement of cost reduction in numerous phases of pro-duction. Added to thes' impressive effectuation , ese roh aided the mills of all threo Champion Divisions in ~n installation or new processes, as well s aoting in the capacity of ''trouble .. shooter" and technic 1 advisor. Claiming both success and failur , earo , during period of bout 35 years, has contributed greatly to Champion•s industrial gro~~h and to its tangible pro perity. The New Eook A wooping rev1 ion of C ampion's aes arch and D v lopment organi~ation 1 tt) which was begun in September 1960• culminated in April 1961 with its virtual discont1n~oe as part of the major r~trenohment progr~~ that af-i'eoted pers' onnel and va~ious departmsntal .t"unot1ons throughout the company, Since that tilne. the teohnioa.J. personnel rema1ning at Champion have been assigned to two distinct general areas or groups. Ono group is responsible tor improvements in existing products and processes; the seoond group, now designated as Development Services, is charged with surveillance and de-velopment or •sential~ ~w products. Technical personnel in the first category include a few individuals in staff capacity at the Ha~ilton headquarters, but the majority have been dis• tributed a010ng the th:t"ee ma.nuf.'aot'Ul"ing Divisionlh Each manutaoturing Division still retains its laboratory facilities, staffed by technicians assigned to apeoitio areas of operations. The work of divisional personnel. whether they be laboratory staff o:- production technologists, is primarily directed to'W'a:rd day-to-day process and materials control. Th$ newl;y Ol"ganized Development Services consists ot approximately 1 S professional people. This group is now engaged in i.ntoll1genoe, survelllanoe;. and develop~ent work, with a ~iew to discovering and developing products and processes that are essentia.lly novel to Cb.ampion*s operations, There remains, however, liaison and mu.:.ual support with the technical groups in the field o£ production, although Developmant Services directs most ot its attention to the probing and s~aening of ideas, proce sea. and business opportunities. The object is to exercise a high degree of selectivity among proposed ideas, and to carry the most promising items on to the statu ol. .. full-!'led.god projects To facilitate its functions, Development Services retains a small labor&• tory of its o•m at Ia!a1.lton. although it can call upon other ox rL'r'\ental. ) ; 12) resources within the company. Otherwise, it is the present policy to ret.y heavily upon outside organizations for consultation and contract research. These outside facilities are employed not only for 1najor feasibility and invostigative studies. but also 1n.~rt.o.1n areas of testing and develop. ment, 'dith this radically revised research organization Champion hopes and ex;. peats that a more selective and intensive approach will yield as maqy. 1! not. lllOre, developments of new prooesse$ and p1"Qduots than otherw-ise might be ac•1eV9d, and tdth great6r e:t'fieiency. In other words, by eXI:lrcising !llOre selectivity, and by more or less divorcing general research from dally OPerating problems, Development Services will be able to produee significant results ~th a limited starr.

Object

Object’s are ‘parent’ level descriptions to ‘children’ items, (e.g. a book with pages).

-

This 215 page document written in 1963 by Corydon Bell covers a wide range of topics relating to Champion Paper and Fibre Company. This document has been separated into five different chapters for easier reading: Chapter 1. Founder and the Enterprise ; Chapter 2. Corporate Image; Chapter 3. Champion and Forest Management; Chapter 4. Champion and Forest Management; Chapter 5. Executive Succession.

-